Thermal spray coating equipment refers to machinery and tools used in the thermal spray coating process, which involves applying a protective or decorative coating to a surface by melting and propelling materials such as metals, ceramics, or polymers onto the substrate. This process is widely used in various industries to enhance the surface properties of materials, including improving wear resistance, corrosion protection, thermal insulation, and aesthetics.

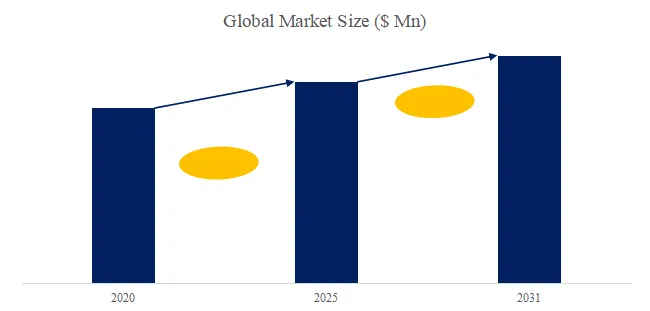

According to the new market research report “Thermal Spray Coating Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Thermal Spray Coating Equipment market size is projected to reach USD 0.42 billion by 2031, at a CAGR of 2.0% during the forecast period.

Figure. Global Thermal Spray Coating Equipment Market Size (US$ Million), 2020-2031

Source: QYResearch, “Thermal Spray Coating Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

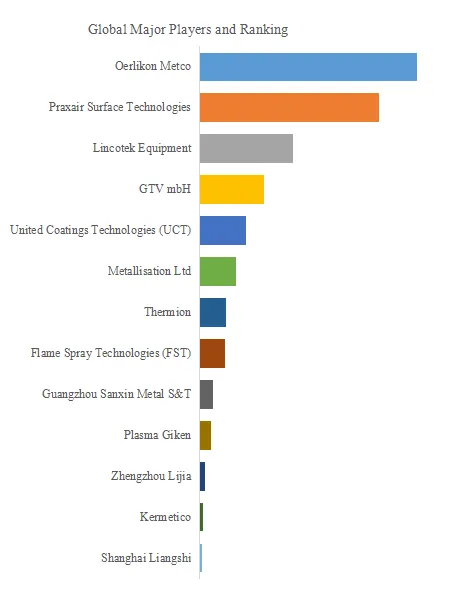

Figure. Global Thermal Spray Coating Equipment Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, “Thermal Spray Coating Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Thermal Spray Coating Equipment include Oerlikon Metco, Praxair Surface Technologies, Lincotek Equipment, GTV mbH, United Coatings Technologies (UCT), etc. In 2024, the global top five players had a share approximately 63.0% in terms of revenue.

Market Drivers for Thermal Spray Coating Equipment:

Surface Protection and Enhancement: Thermal spray coatings provide excellent protection against wear, corrosion, oxidation, and erosion, extending the lifespan and performance of components and equipment in industries such as aerospace, automotive, energy, and manufacturing.

Versatility in Coating Materials: Thermal spray technology supports a wide range of coating materials, including metals, ceramics, polymers, and composites, allowing for customization of coatings to meet specific performance requirements and application needs.

Cost-Effective Surface Solutions: Thermal spray coatings offer a cost-effective solution for enhancing surface properties compared to traditional methods such as plating or cladding, reducing the need for expensive materials and processes.

Enhanced Performance: Thermal spray coatings can improve the mechanical properties, thermal insulation, electrical conductivity, and surface finish of components, enabling them to withstand harsh operating conditions and meet stringent performance standards.

Industry Demand: Increasing demand for high-performance coatings in industries such as aerospace, automotive, oil and gas, power generation, and electronics is driving the adoption of thermal spray coating equipment for surface protection and enhancement applications.

Market Challenges for Thermal Spray Coating Equipment:

Process Control and Optimization: Achieving consistent coating quality, thickness, adhesion, and porosity control across large and complex surfaces requires precise process control, monitoring, and optimization, posing challenges in achieving uniform coating properties.

Material and Equipment Maintenance: Proper maintenance of thermal spray equipment, including guns, nozzles, feeders, and powder supply systems, is essential to ensure reliable operation, consistent coating quality, and prolong equipment lifespan.

Health and Safety Regulations: Handling and spraying of fine coating materials and gases in thermal spray processes pose health and safety risks to operators, requiring compliance with stringent regulations, proper ventilation, and personal protective equipment.

Environmental Concerns: Thermal spray processes may generate airborne particles, fumes, and waste materials that can impact air quality and environmental sustainability, necessitating proper waste management practices and emissions control measures.

Competitive Landscape: Competition from alternative surface coating technologies, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), challenges the market position of thermal spray coating equipment, requiring continuous innovation and differentiation to remain competitive.

About The Authors

Chen – Senior Analyst

Email: chenglijun@qyresearch.com

Lijun Chen is a senior research analyst who has 8 years’ experience in semiconductor, materials, chemicals and mineral resource, etc..

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp