Thinning grinding wheels are specialized abrasive tools designed for the precise thinning of semiconductor wafers, particularly in the production of advanced integrated circuits and power devices. These wheels are integral to the back-end processing stages of semiconductor manufacturing, where they are employed to reduce wafer thickness, thereby enhancing the performance and miniaturization of electronic components.

The composition of thinning grinding wheels typically includes high-performance abrasives such as diamond or cubic boron nitride (CBN), bonded using metal, resin, vitrified, or electroplated matrices. The choice of bonding material and abrasive type is crucial, as it influences the wheel’s durability, cutting efficiency, and thermal conductivity. Advanced bonding technologies, such as metal and vitrified bonds, offer superior heat resistance and extended tool life, which are essential for maintaining precision during the thinning process.

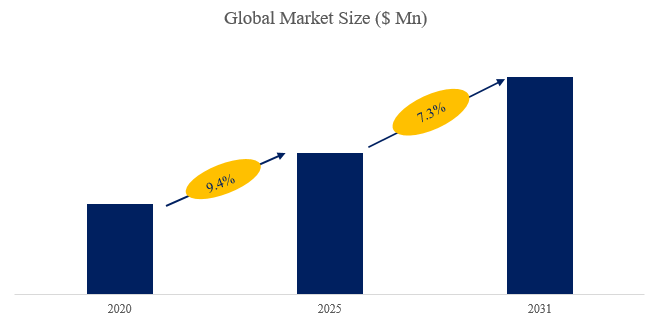

According to the new market research report “Thinning Grinding Wheels – Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Thinning Grinding Wheels market size is projected to reach USD 0.77 billion by 2031, at a CAGR of 7.3% during the forecast period.

Figure. Global Thinning Grinding Wheels Market Size (US$ Million), 2020-2031

Source: QYResearch, “Thinning Grinding Wheels – Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

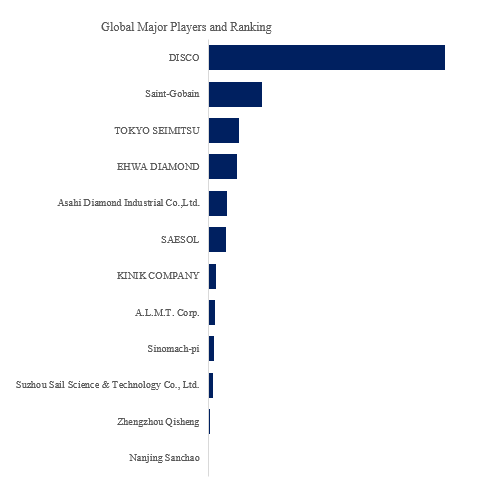

Figure. Global Thinning Grinding Wheels Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, “Thinning Grinding Wheels – Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Thinning Grinding Wheels include DISCO, Saint-Gobain, TOKYO SEIMITSU, EHWA DIAMOND, Asahi Diamond Industrial Co.,Ltd., SAESOL, KINIK COMPANY, A.L.M.T. Corp., Sinomach-pi, Suzhou Sail Science & Technology Co., Ltd., etc. In 2024, the global top 10 players had a share approximately 68.0% in terms of revenue.

Market Driving Factors

Advancements in Semiconductor Technology: The continuous evolution of semiconductor devices, including the adoption of 5G, AI, and IoT technologies, necessitates the production of smaller, more efficient chips. This drives the demand for precise wafer thinning to achieve the desired performance metrics.

Technological Innovations in Grinding Tools: Developments in grinding wheel materials and bonding techniques have enhanced grinding efficiency and tool longevity. Innovations such as ultra-fine diamond abrasives and resin-bonded wheels contribute to improved surface finishes and reduced material wastage.

Expansion of Semiconductor Fabrication Facilities: Significant investments in new fabrication plants by major semiconductor manufacturers are propelling the need for high-precision grinding wheels to meet the increasing production demands.

Growing Demand for 300mm Wafers: The industry’s shift towards larger wafer sizes for better yield and cost efficiency is increasing the demand for thinning grinding wheels tailored for 300mm wafers.

Market Restraints

High Initial Investment Costs: The specialized equipment and technology required for wafer grinding are capital-intensive, posing a barrier for smaller semiconductor manufacturers or those in emerging markets.

Technical Complexity: The wafer grinding process demands skilled operators and precise control to avoid damaging the delicate wafers. Inadequate handling can lead to increased production costs and reduced yields.

Supply Chain Challenges: Fluctuations in the availability and cost of raw materials, such as diamond abrasives, impact the production and pricing of grinding wheels. Additionally, global supply chain issues can affect the timely availability of these specialized tools.

Environmental and Regulatory Constraints: Stringent environmental regulations and the need for sustainable manufacturing practices are compelling companies to develop eco-friendly grinding solutions, which may require additional research and development investments.

About The Authors

Li Feifei – Lead Author

Email: lifeifei@qyresearch.com

Li Feifei is a technology & market senior analyst specializing in environmental chemical and mechanical equipment. Li has 9 years’ experience in semiconductor and focuses Thinning Grinding Wheels , marine exhaust gas cleaning systems (marine scrubbers/EGCS), direct air capture (DAC or DACCS), spectrometers, road sweepers and other environmental sanitation equipment, gear grinding, bearings, lithography machines, Thinning Grinding Wheels s, etc. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp