Wafer thinning machines, also called grinders, use a centrally located robot to move wafers from the input station to the measurement station. After that, the wafer moves to the polishing station and the cleaning station in sequence. The robot can move the wafer from the cleaning station to the measuring station for measurement after grinding or directly to the output station.

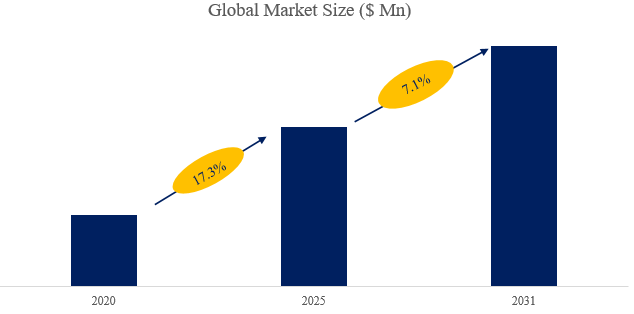

According to the new market research report “Wafer Thinning Machine – Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Wafer Thinning Machine market size is projected to reach USD 1.7 billion by 2031, at a CAGR of 7.1% during the forecast period.

Figure. Global Wafer Thinning Machines Market Size (US$ Million), 2020-2031

Source: QYResearch, “Wafer Thinning Machine – Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

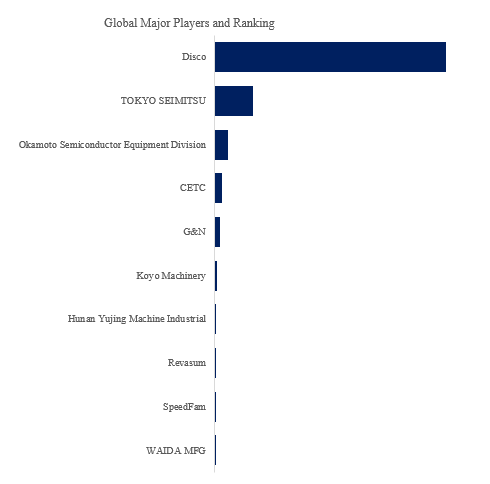

Figure. Global Wafer Thinning Machines Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, “Wafer Thinning Machine – Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Wafer Thinning Machines include Disco, TOKYO SEIMITSU, Okamoto Semiconductor Equipment Division, CETC, G&N, Koyo Machinery, Hunan Yujing Machine Industrial, Revasum, SpeedFam, WAIDA MFG, etc. In 2024, the global top five players had a share approximately 89.0% in terms of revenue.

In terms of product type, currently Full-Automatic is the largest segment, hold a share of 51.7%.

In terms of product application, currently 300mm Wafer is the largest segment, hold a share of 83.8%.

Market Driving Factors

Technological Advancements in Semiconductor Manufacturing: As the demand for smaller, more powerful, and energy-efficient electronic devices grows, semiconductor manufacturers are continuously advancing their processes to meet these demands. This includes the need for thinner, more precisely engineered wafers, driving the demand for high-performance Wafer Thinning Machines. Fully automatic Wafer Thinning Machines, known for their precision and ability to handle larger volumes, are particularly in demand to meet these stringent manufacturing requirements.

Miniaturization of Electronic Devices: The global trend towards smaller, more compact electronic devices—such as smartphones, wearables, and IoT devices—requires thinner semiconductor wafers. As a result, there is a growing demand for wafer thinning solutions that can maintain high quality while reducing thickness. Fully automatic Wafer Thinning Machines are the preferred solution, as they offer high precision and productivity.

Surge in Semiconductor Demand: The semiconductor industry is experiencing significant growth, driven by the rise in demand for various electronic applications, including computing, communication, and automotive systems. As the industry’s focus shifts towards advanced technology nodes, the demand for larger wafers, particularly 300mm wafers, is growing. These trends are contributing to the expansion of the Wafer Thinning Machine market, especially in regions such as APAC, which dominate semiconductor manufacturing.

Shift Towards Fully Automated Solutions: Fully automated Wafer Thinning Machines are gaining popularity due to their higher efficiency, reduced labor costs, and the ability to maintain consistency across large batches. As semiconductor manufacturers continue to scale production, automation becomes increasingly essential to meet high-volume production requirements without compromising quality.

Market Restraints

Process Complexity: The wafer thinning process for wafers involves high-precision techniques and is technically challenging. The instability of the process may lead to quality issues, affecting market confidence.

Intensifying Competition: As the downstream market rapidly develops, more companies are entering the field, and market competition is becoming increasingly intense. This may lead to price wars and margin compression.

Technological Iteration: With the fast pace of technological updates, the introduction of new technologies and equipment may quickly render existing equipment obsolete. Companies need to continue investing in research and development to maintain competitiveness.

About The Authors

Li Feifei – Lead Author

Email: lifeifei@qyresearch.com

Li Feifei is a technology & market senior analyst specializing in environmental chemical and mechanical equipment. Li has 9 years’ experience in semiconductor and focuses Wafer Thinning Machines , marine exhaust gas cleaning systems (marine scrubbers/EGCS), direct air capture (DAC or DACCS), spectrometers, road sweepers and other environmental sanitation equipment, gear grinding, bearings, lithography machines, Wafer Thinning Machines s, etc. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp